Something went wrong... Please try again.

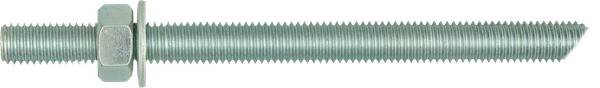

R-STUDS Metric Threaded Rods - Steel Class 1.4529 HCR, Flat Head

Threaded rod made out of an austenitic special steel 1.4529 HCR classified in the highest corrosion resistance class

Features and benefits

- Stainless steel 1.4529 HCR is characterized by its high resistance to local corrosion phenomena, such as crevice corrosion, pitting, or chlorine-induced stress corrosion cracking

- It demonstrates excellent mechanical properties and can be used in a wide temperature range

- In contact with sulphuric or phosphoric acid, or chlorides and salts, it offers excellent resilience and resistance to wear

- High-performance bonded anchors offer high load-bearing capacities

- Can be post-installed through fixture in some cases. (Consult technical advisory service)

- Flat head for quick manual installation without a setting tool

Product information

Size |

Product Code |

Anchor |

Fixture |

|||||

Diameter |

Length |

Max. thickness tfix for: |

Hole diameter |

Max. thickness tfix for: |

||||

d |

L |

hnom, 6d |

hnom, 12d |

df |

hnom,min |

hnom, 12d |

||

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

||

M8 |

R-STUDS-08110HCRFL |

8 |

110 |

52 |

4 |

9 |

40 |

4 |

M10 |

R-STUDS-10130HCRFL |

10 |

130 |

58 |

- |

12 |

48 |

- |

M12 |

R-STUDS-12160HCRFL |

12 |

160 |

73 |

1 |

14 |

65 |

1 |

M16 |

R-STUDS-16190HCRFL |

16 |

190 |

75 |

- |

18 |

71 |

- |

M20 |

R-STUDS-20260HCRFL |

20 |

260 |

117 |

- |

22 |

117 |

- |

Applications

- Shipbuilding

- Offshore technology

- Swimming pool technology

- Plants in the chemical industry

- Heat exchangers and evaporators

- Flue gas desulphurization plants

- Tanks for aggressive chemical products

- Tunnel construction

Installation guide

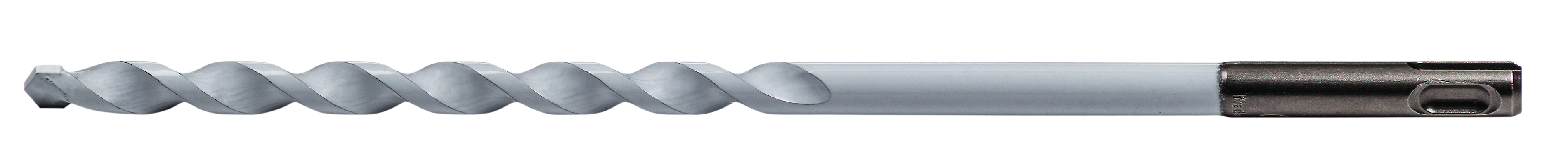

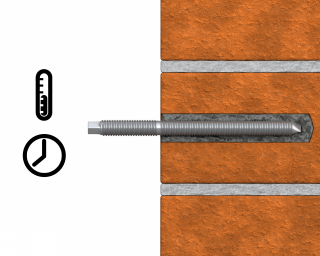

- Drill hole to the required diameter and depth for stud size being used.

- Clean the hole thoroughly with hand pump and hole brush

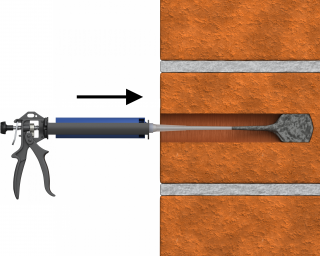

- If required, insert the mesh sleeve into position

- Fill hole with the required resin to the recommended fill level. (Follow the relevant instructions for the resin product)

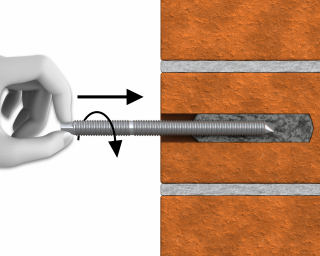

- Insert the threaded stud slowly and with a slight twisting motion, until the required embedment depth is reached

- Leave undisturbed until curing time of resin has elapsed

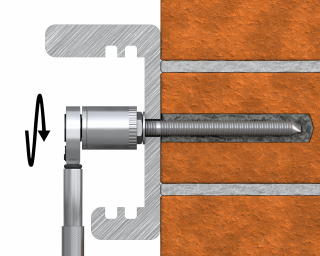

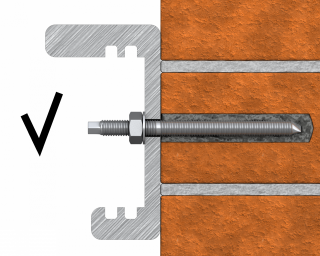

- Attach fixture and tighten the nut to the required installation torque

Contact us to get information about product availability and its price