Something went wrong... Please try again.

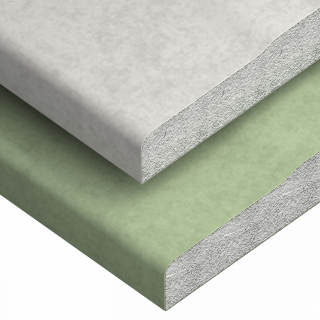

R-XPC-300 Express Cement

Express Cement - single component, ready to use repair mortar based on polymers.

Features and benefits

- Repairing mortar is resistant to changing weather conditions (from -20°C to +70°C) and UV radiation.

- Mortar can be applied to slightly wet surfaces.

- Saves time - no need for pre-mixing.

- Mortar is suitable for indoor and outdoor applications.

- Excellent adhesion to common building substrates.

Base material

-

Concrete

-

.png)

Aerated Concrete Block

-

Ceramics

-

Solid Brick

-

Wood

-

Plasterboard

-

Gypsum Fibreboards

-

Masonry

Applications

- Repairing masonry joints and roof tiles

- Repairing chipped edges

- General repair work

Installation guide

- The surface, that repair mortar will be applied on should be clean, free of dust, free of old seal and other substances that might weaken the adhesion.

- Before using the product, it is recommended to perform an adhesion test on the intended substrate.

- Cut the tip of the applicator to the appropriate diameter.

- Outflow of the mortar should be regulate by the appropriate pressure on the application gun.

- Mortar Fix-Pro hardens by the reaction with moisture from the air. For that reason ensure well-ventilated conditions.

- After completing the application, put the tip on the applicator to protect the mass against hardening.

- Remove excess of uncured mortar from surfaces, tools, hands using paper towel.

- Remove cured mass from tools or surfaces mechanically, then wash with water and/or detergent.

Contact us to get information about product availability and its price