Need more information about Rawlplug? go to brand site

Effective and secure fastening, but also aesthetically pleasing installation – these are the goals of every professional and expert. It is extremely important to make sure that you match your plug as much as possible to the type of substrate in which it will be used.

Please note:

This article focuses only on installing wall plugs depending on the place of installation. Remember that when choosing plugs, you must absolutely take into account the type and weight of the element to be fixed, as well as other considerations.

Types of popular wall plugs

Can all plugs be used for fixing in any type of substrate? While it is best to choose a dedicated fixing, there are also some universal wall plugs that will perform well in a variety of conditions. We will describe them below.

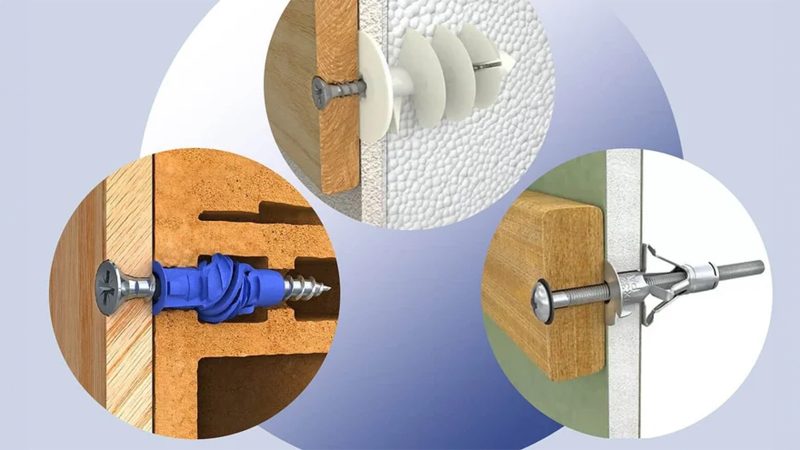

Some of the most popular plugs broken down by the substrate in which they can be used include the following:

1. plugs for drywall, chipboard and wood-based panels

2. plugs for hollow surfaces

3. plugs for concrete

4. plugs for expanded polystyrene and other insulation panels

You can also get universal fixings that can be used in a variety of materials, including the three basic ones: concrete, drywall, and hollow substrates such as vertically perforated bricks and hollow masonry units.

Which plugs are universal?

If you are looking for the right wall plug at the stage of construction or finishing of a new building, you won’t have any problems matching them to the substrate, as you can be sure of the materials used. Things will be different when it comes to housing from the resale market or certain renovation works. We cannot always be sure of the kind of walls we are dealing with.

In such situations, the perfect solution is a universal plug, which we can use for drywall, concrete, timber, and hollow masonry units. The range of the best wall plugs on the market includes Rawlplug’s classic universal plugs:

- 4ALL plugs

- UNO plugs

- RAWLNUT flexi-plugs

Universal plugs are perfect for unreliable substrates as well as for hollow spaces such as vertically perforated bricks and hollow masonry units.

What are the best plugs for drywall?

How to choose the right plug for fixing light loads in drywall? There are quite a few fixings to choose from here, so you can focus on your aesthetic and technical requirements (as installation technique is important in this case), as well as on the parameters of the elements to be installed: the weight, size, and method of fixing.

Our drywall plugs include the following:

- Rawlplug’s TAP-IT fixings for plasterboard provide the easiest and fastest way of fixing elements to drywall. These hammer-in fixings are made of steel and they only need to be tapped into the base material, without the need to drill a hole or use additional installation accessories

- self-drilling plasterboard fixings are used both to join panels together and to fix small loads to them. Their design makes them quick to install, as no holes need to be drilled. You can install them with a manual or electric screwdriver. You can choose a nylon or a metal plug, which come either with or without matching screws. Use with a screw or hook

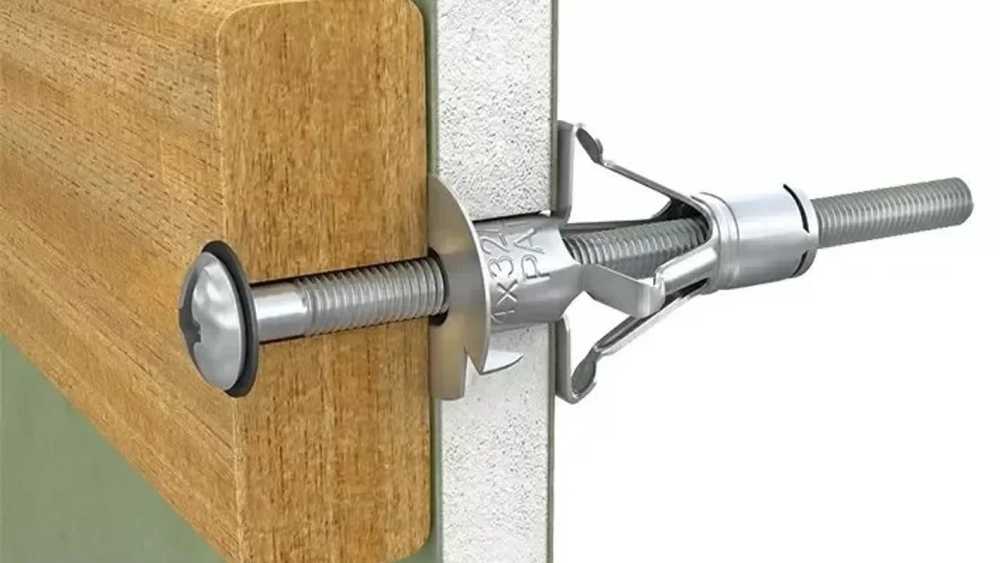

- Interset metal plugs available with screws or hooks for various applications. They are used not only for drywall, but also for wood-based and cement-gypsum boards. Choose this type of plug if you want to be able to easily replace the fixed element and reinstall it with the same screw. In addition, these fixings are particularly resistant to loads, as they are made of steel and their arms expand over a large surface.

- metal spring toggles for drywall featuring long “wings” that allow the load to be distributed over a larger surface. They can be used not only for drywall, but also for wood-based panels and PVC profiles. They are also suitable for fixing elements in ceilings.

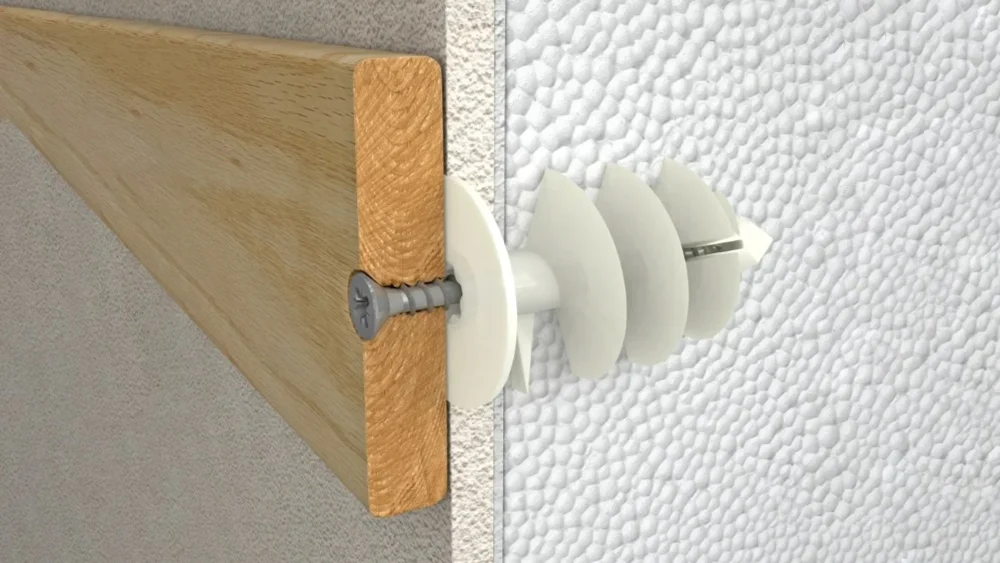

How to choose the right plug for expanded polystyrene?

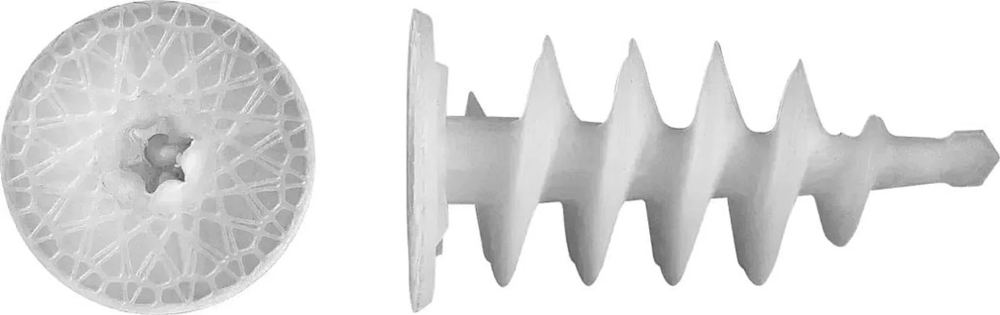

EPS fixings have a distinctive spiral shape and are usually made of white plastic. They are used to install electrical, ventilation and air conditioning systems as well as other light loads directly in insulated facades.

These specialised plugs are designed to prevent plaster damage and to match most screw diameters. The plate allows them to installed perfectly flush with the plaster surface, preventing heat losses and ensuring an aesthetically pleasing finish.

They are provided with a TX/HEX socket. To install plugs in EPS panels, you can use ordinary drill bits and tools.

This is what Rawlplug’s EPS plug looks like:

How do I choose a fixing for expanded polystyrene? Fortunately, the task is not difficult, you just need to determine the length you need. The most common dimensions for EPS plugs are the following:

- 50 mm

- 80 mm

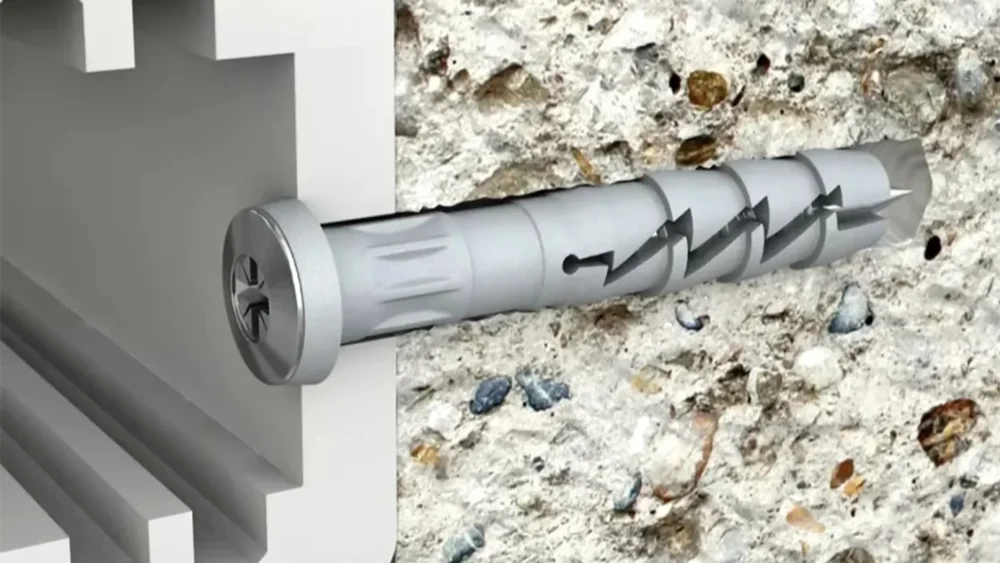

Which plugs will be best for solid brick and for concrete?

The perfect solution for solid materials such as solid brick and concrete is provided by universal plugs. In addition to these, you can also use hammer-in fixings for quick installation or FIX plugs.

What are the best plugs for masonry and concrete?

To obtain the best plug performance, choose those that are specifically designed for solid surfaces. They include the following:

- FIX plugs – the right type of plug for solid surfaces, where they perform best. An engineered surface and a two-way expansion mechanism, giving it excellent performance in concrete and solid brick. The anti-rotation fins prevent spinning during tightening of the screw.

- Frame fixings – they may prove best for fixing hard materials (e.g., steel components) and heavy loads in concrete, solid brick, as well as stone. Their special design provides expansion along multiple axes. They are made of nylon for excellent durability and long life.

- Hammer-in fixings for quick installation – the best choice if you want quick and easy installation in solid materials. Installation with a hammer makes it easier to fix components in series. The screw thread allows you to remove the fixing, if required. The nylon design ensures high resistance to external conditions in the case of these plugs for brick and concrete.

Universal plugs for hollow surfaces

Are you sure your wall is built of hollow masonry units or vertically perforated bricks? If so, choosing the right plugs will not be as difficult as it may seem. All classic universal plugs will be suitable for installing elements in such walls.

Which plugs are suitable for hollow masonry units?

Choose plugs for hollow masonry units and other hollow surfaces to meet the installation requirements of your specific situation in the best possible way. Pay attention to their application and load capacities. It is also important to make sure that your fixing solution is visually coherent with the place of installation.

How do I choose the right plug for a specific surface type?

When looking for the right plug for the surface in which it will be installed, you can use professional help, online advice, your own experience, but also appropriately structured categories and filters in the search engines of tried-and-tested sites such as eRawlplug. You will find a very wide range of plugs there.

All you need to do is select the relevant substrate and the system will filter the search results, matching the products to your selection. You can also look for the categories that interest you most and narrow down your search by further parameters. An extensive filter system will allow to choose the perfect fixing for you.